Sop Manual Handling Pdf - Ebook And Manual Free

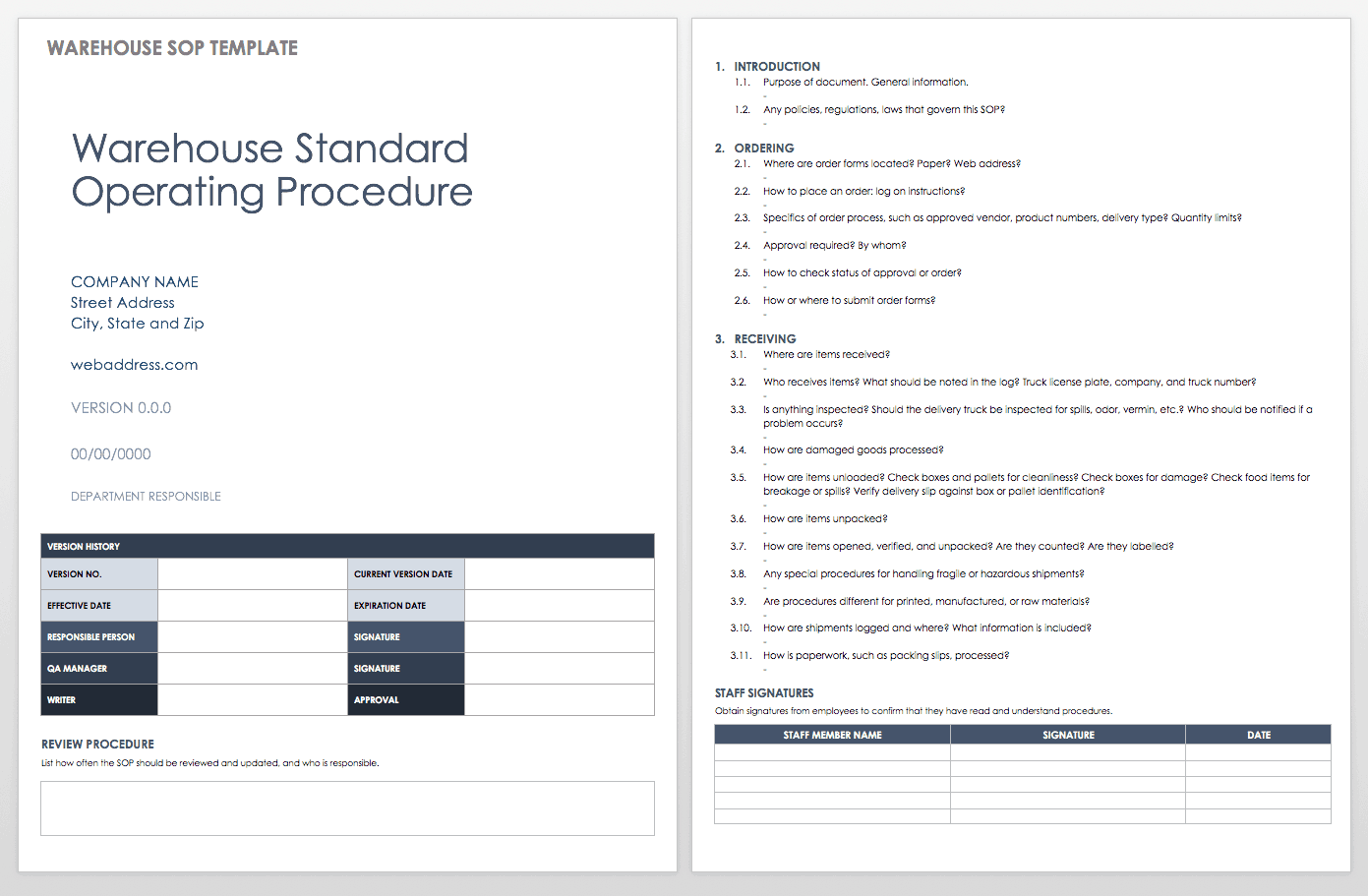

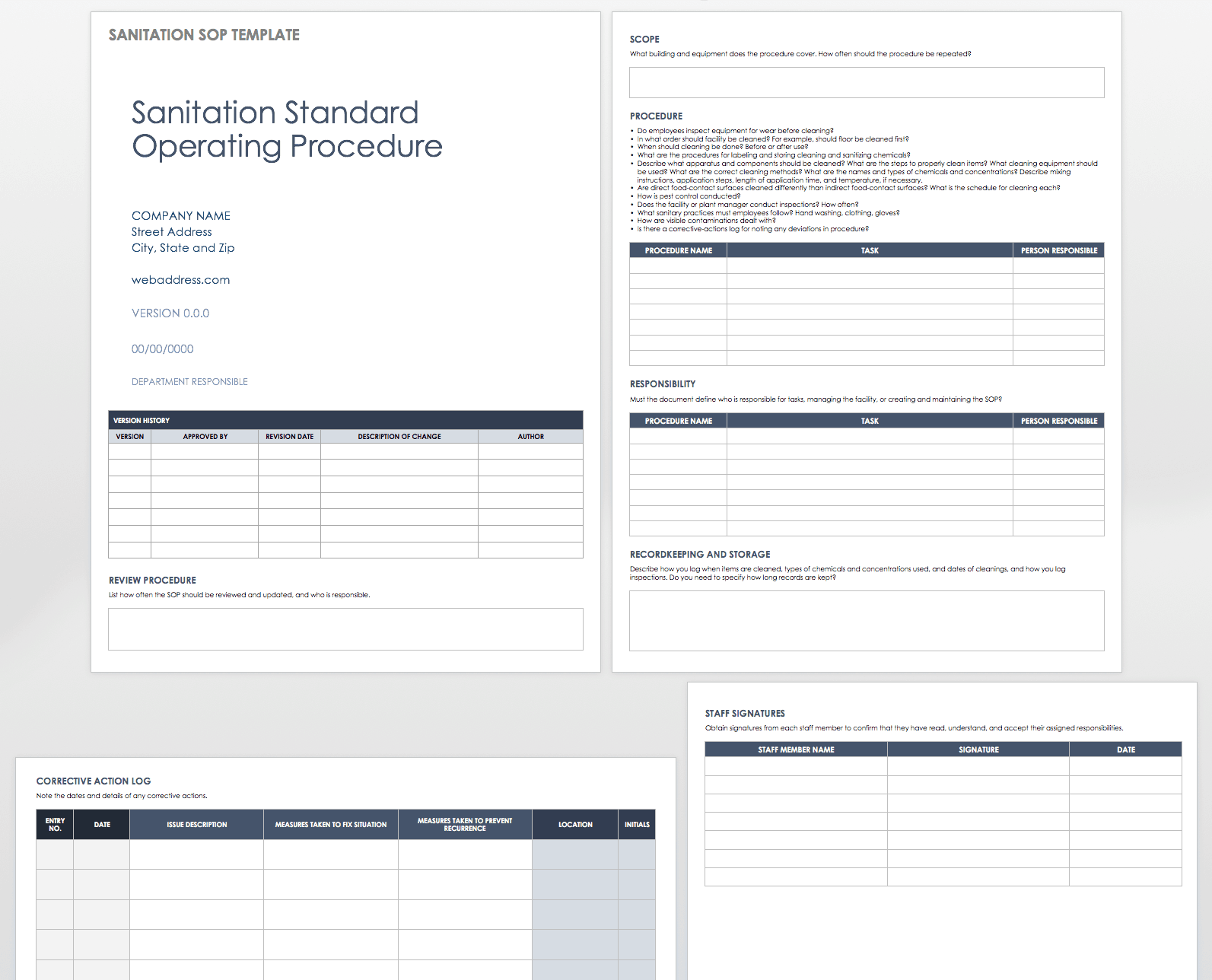

40 scope this sop covers all aspects of receipts storage issues handling status reports as well as safety and security requirements for.

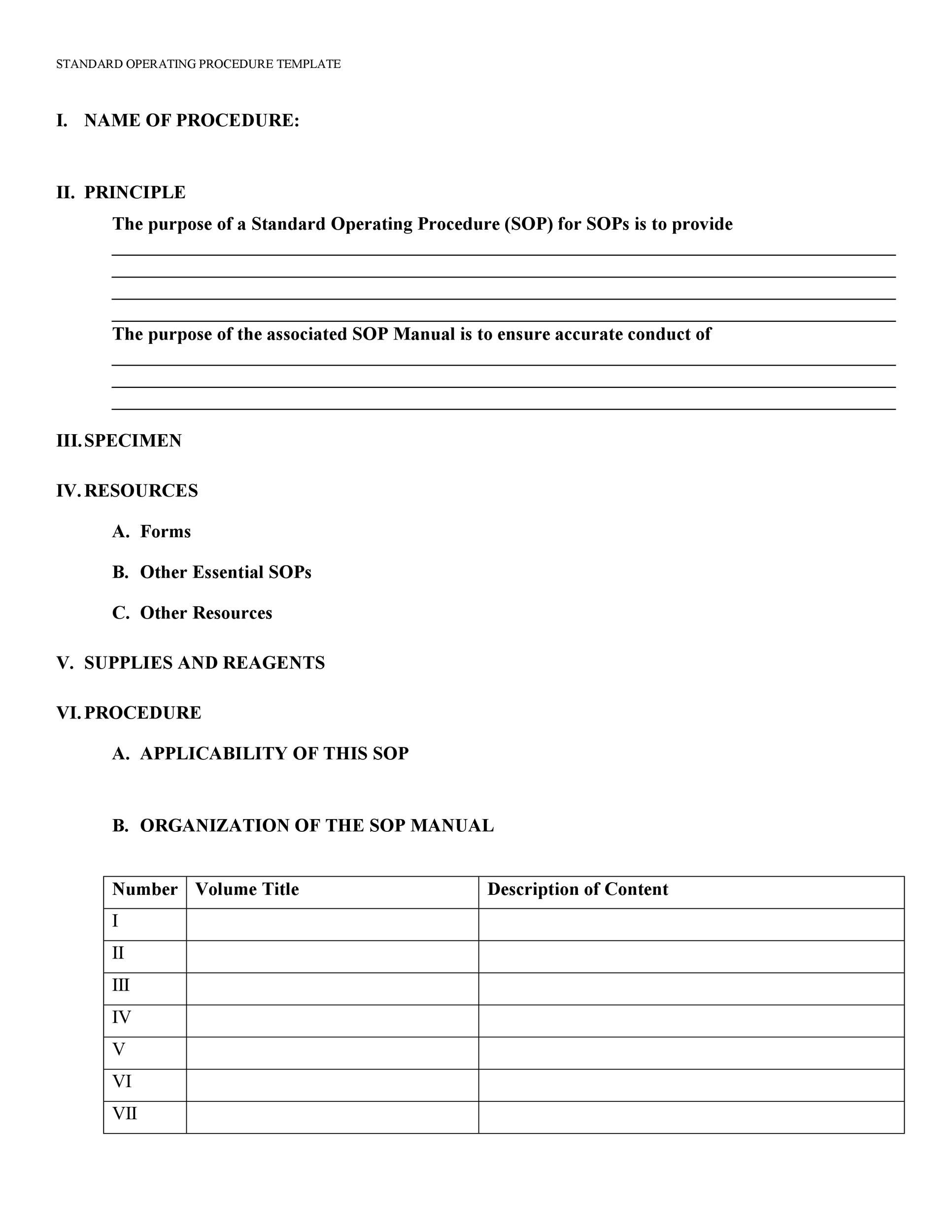

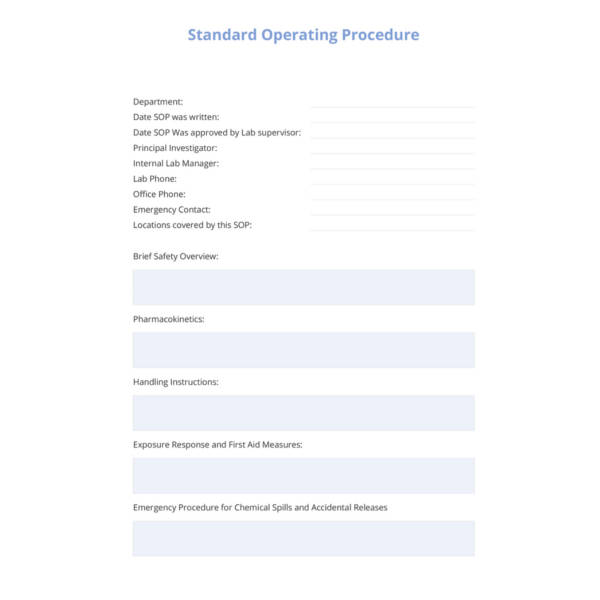

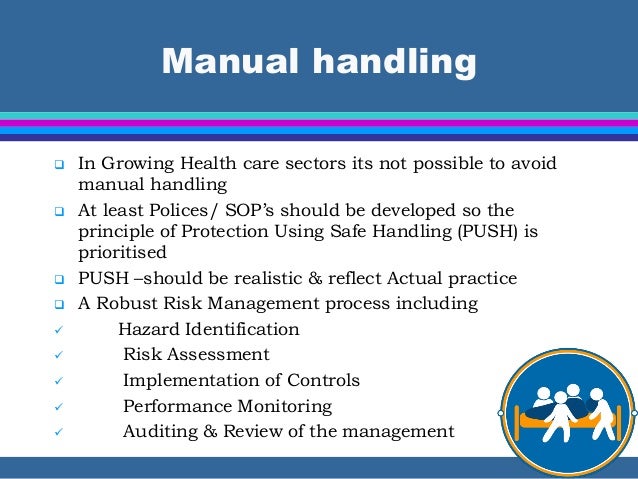

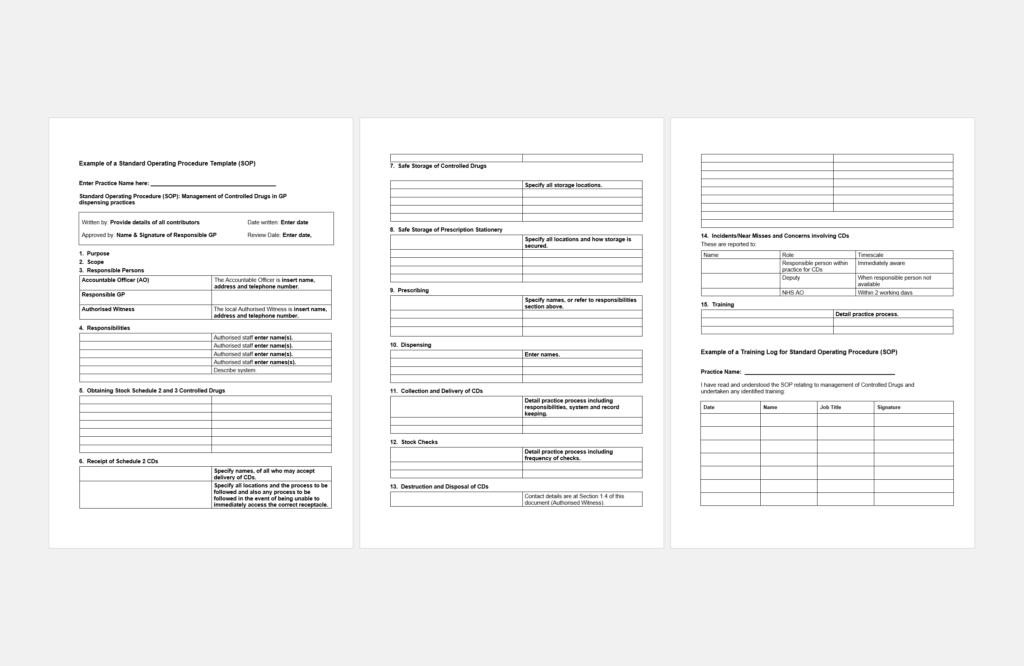

Sop manual handling pdf. 040815 standard operating procedure manual handling workplaces where hazardous manual tasks take place have an obligation to ensure the health and safety of their staff. Purpose the purpose of this sop is to provide a process for identifying and controlling the risk associated with hazardous manual handling activities 2. Introduction to the sop this standard operating procedures sop document contains the operational steps that stakeholders of the air cargo supply chain should follow when using e awb. In addition to following these generic procedures stakeholders will also have.

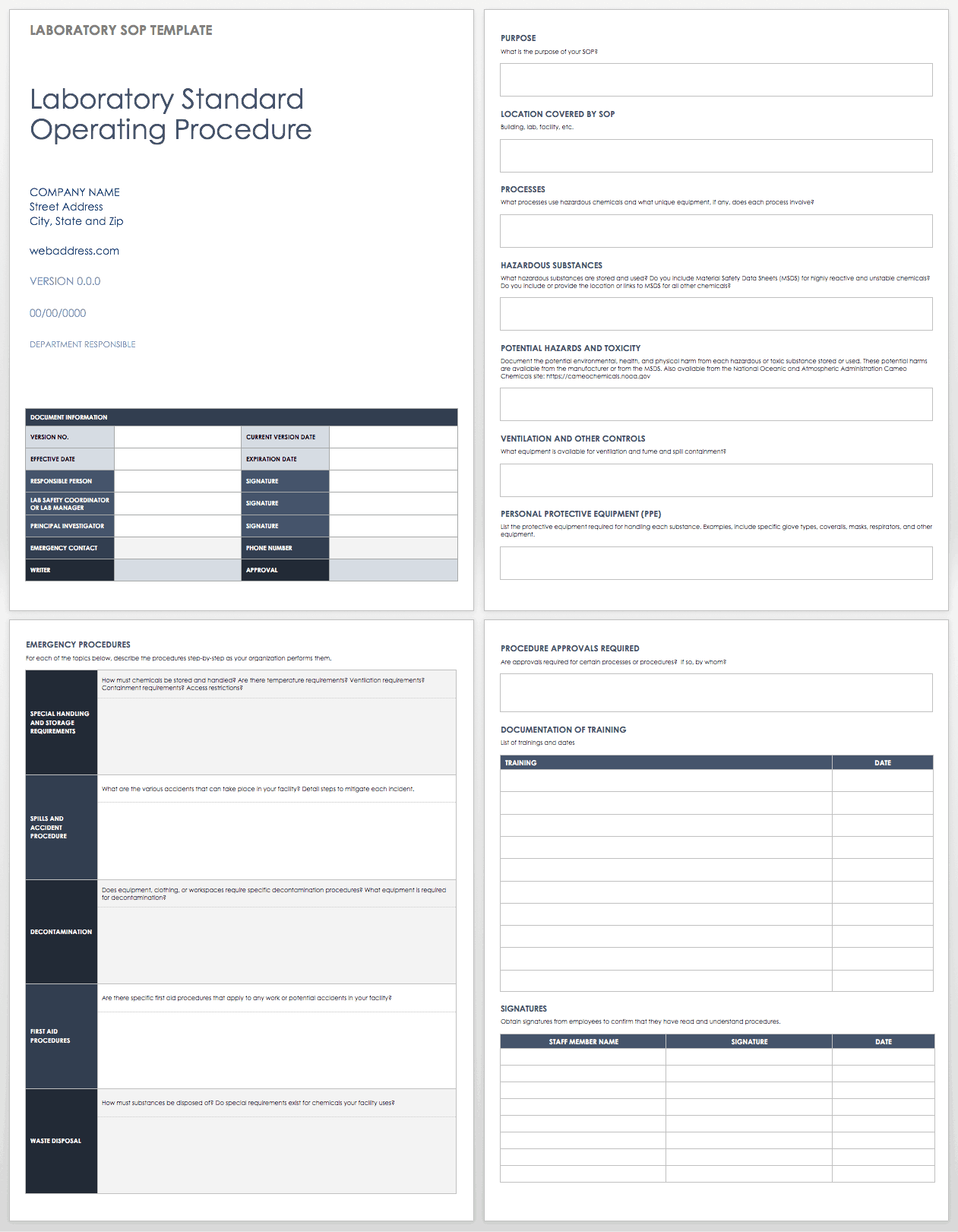

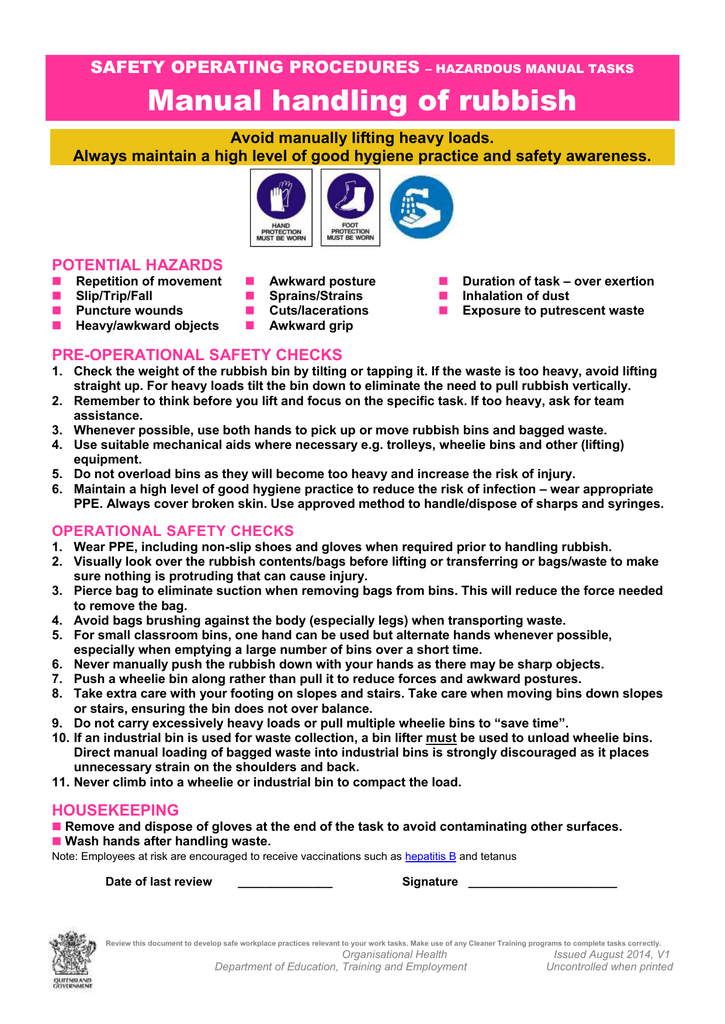

Identifying hazardous manual tasks. Final emergency procedure all emergencies call 56666. Manual handling policy and procedures. Display emergency procedures in the area.

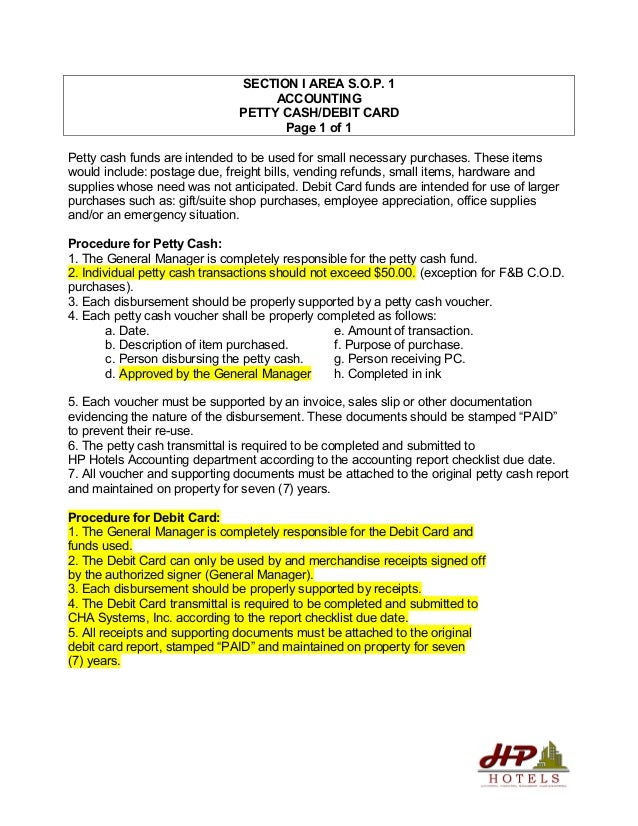

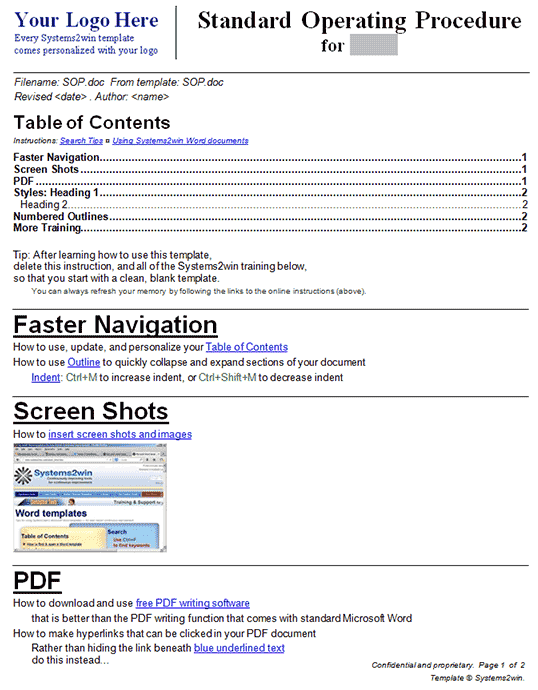

Plan the lift get help use mechanical devices reduce double handling avoid reaching or holding above head height and repetitive actions take breaks. 14 glove and utensils use policy. It is designed to be used as an adjunct to teaching safety procedures and to act as a reminder to users prior to machine use. These procedures are not location specific.

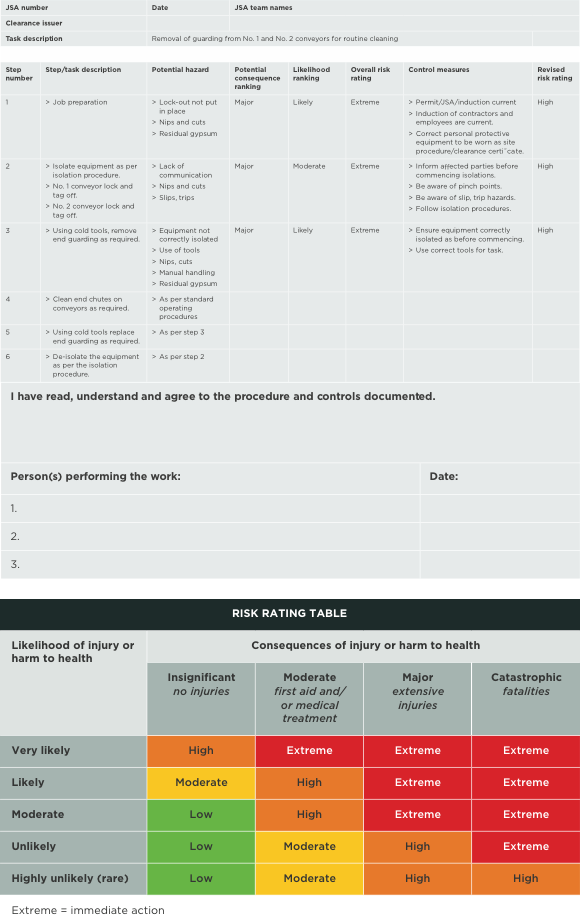

6 march 2013 uncontrolled when printed version. Maintenance of stock records. 0 6 m a n u a l h a n d l i n g p a g e 2 4 1 procedures risk management beatas integrated risk management strategy provides a structured framework for the identification analysis and treatment of all situations of risk. Issue of materials to users within the organization.

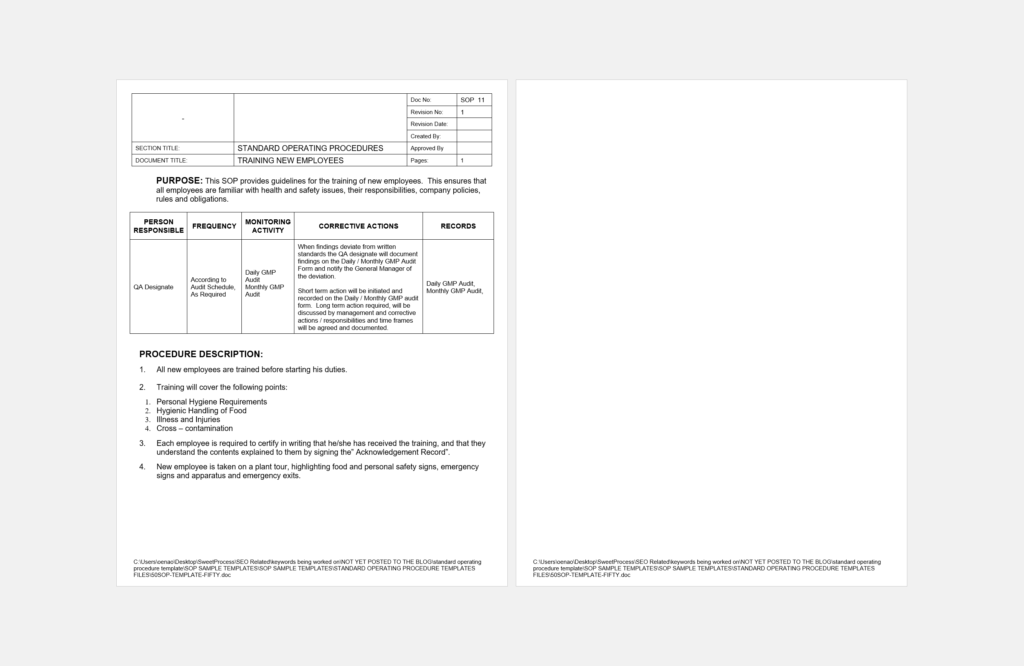

Lifting pushing and pulling manual handling lifting pushing and pulling manual handling overview. Our procedures for manual handling. For the purpose of this sop materials handling has been separated into mechanical handling and manual handling. Standard operating procedure manual handling issued.

Submission of management information reports. Clean up procedures for task leave the area where it was used in a safe clean and tidy state. 81 mechanical handling 811 general requirements lifting equipment selection shall be based on a risk assessment and shall be suitable for the task for which it will be used. Approval managing director 3.

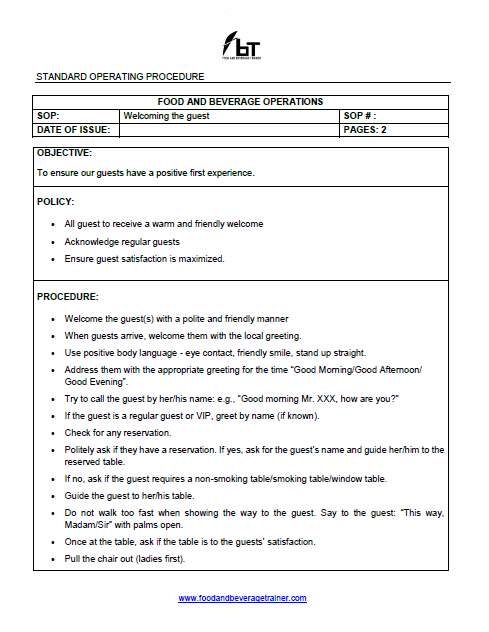

Work procedures ergonomically designed tools and equipment will help eliminate or reduce risk factors associated with hazardous manual tasks. Gloves or utensils will be used for handling all ready to eat foods and when there are cuts sores burns or lesions on the hands of food handlers. Pdf 62194 kb docx 36729 kb reports. P o l 4.

Sop food safety hygiene sop food safety hygiene page 8 chew gum or eat candy only in the area designated for employees to eat.